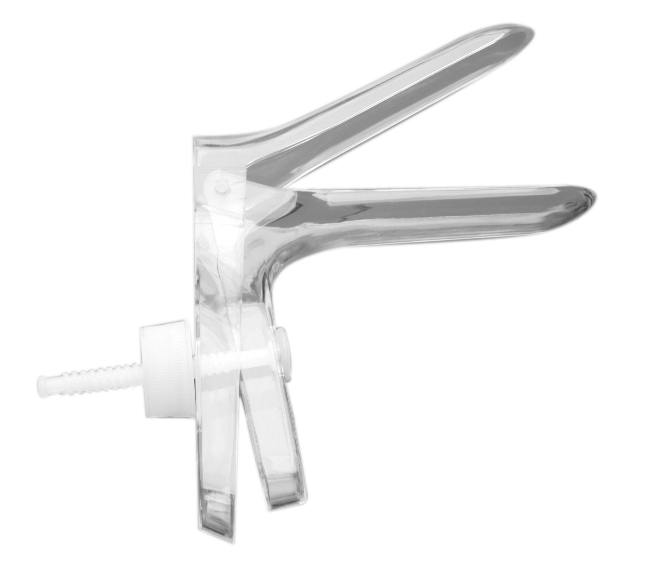

Screw Type D

Screw Type D

Have you ever heard of a screw type vaginal speculum? It’s a gynecological instrument commonly used in hospitals and clinics to help diagnose and treat gynecological diseases. While this tool might seem intimidating, it’s actually very easy to use with the right instructions. In this article, we’ll cover everything you need to know about using a screw type vaginal speculum so you can feel confident in your ability to use it.

Description

| Ref. No.: |

Size: |

Packing: |

Ctn size: |

| NMDE710117 |

S |

1pc/poly bag, 100PCS / CTN |

50x38x29cm |

| NMDE710118 |

M |

1pc/poly bag, 100PCS / CTN |

50x38x29cm |

| NMDE10119 |

L |

1pc/poly bag, 100PCS / CTN |

50x38x29cm |

Introduction to Screw Type Vaginal Speculum

A screw type vaginal speculum is a medical device used by gynecologists during pelvic examinations. It is inserted into the vagina to visualize the cervix and other structures in the pelvis. The screw type vaginal speculum has a handle that can be rotated to open or close the blades. The blades are opened by rotating the handle in a clockwise direction and closed by rotating the handle in a counter-clockwise direction. To insert the screw type vaginal speculum, the gynecologist will lubricate the tip of the instrument with water-soluble lubricant. The patient will then be asked to lie down on her back with her legs spread apart. The gynecologist will insert the speculum into the patient's vagina and rotate the handle to open the blades. Once the blades are opened, the gynecologist can visualize the cervix and other structures in the pelvis. To remove the screw type vaginal speculum, the gynecologist will rotate the handle in a counter-clockwise direction to close the blades. The instrument will then be slowly withdrawn from the patient's vagina.

How to Use Screw Type Vaginal Speculum

If you are planning on using a screw type vaginal speculum for your next gynecological exam, there are a few things that you should know. First and foremost, it is important to make sure that the speculum is properly lubricated before use. This will help to ensure that the exam is as comfortable as possible for both you and your patient. Once the speculum is properly lubricated, you will need to insert it into the vagina. To do this, simply hold the barrel of the speculum in one hand and gently insert it into the vagina with the other hand. Once the barrel of the speculum is inside of the vagina, slowly twist the handle in a clockwise direction. This will cause the blades of the speculum to open up and allow you to see inside of the vagina. Once you have finished your examination, simply reverse the process that you used to insert the speculum. Hold onto the barrel of the speculum with one hand and twist the handle in a counter-clockwise direction with your other hand. This will cause the blades of the speculum to close back up and allow you to remove it from the vagina.

Some Interesting Facts about Screw Type Vaginal Speculum,

The screw type vaginal speculum is a great tool for doctors and gynecologists to use during examinations. Here are some interesting facts about this type of speculum:

-The screw type vaginal speculum was invented by Dr. J. Marion Sims in 1845.

-This type of speculum is made up of two blades that are hinged together at the top, and a screw mechanism that allows the doctor to open and close the blades.

-The screw type vaginal speculum is usually made of metal, but there are some newer plastic models available as well.

-When using this type of speculum, the doctor will insert it into the patient's vagina and then use the screw mechanism to open the blades. This will allow them to get a good view of the inside of the vagina and check for any problems.

-After the examination is complete, the doctor will close the blades and remove the speculum from the patient's vagina.

Screw Type D correspond of a head, cutter, vestments and the tip or point. The point of a screw is the first part of the screw to make contact with the material you ’re working with. Different types of screw points serve different purposes. For illustration, some are more suited for distance essence or soft accoutrements than others, while other points are designed for misaligned holes or minimizing the threat for face cracking. Use this screw point type map to find the stylish screw for your design.

Tapping Screw Points

Still, tapping screws are a popular choice because they don't bear a airman hole to begin, If you ’re looking for thin distance essence screw point types. These screws are externally threaded and produce — or “ valve” — their own vestments in thin distance essence andnon-metal accoutrements.

Some types of tapping Screw Type D include

Type A Type A screws have coarse vestments that make them useful when you need to drill or nest a hole in thin distance essence, resin plywood, asbestos combinations and other accoutrements. They're threading screws and not recommended for new designs.

Type B You can use a fine- thread Type B screw fornon-ferrous featherlight and heavy essence, plastics, resin plywood and other accoutrements.

Type AB Type AB screws are thread forming screws analogous to both Type A and Type B points. It has the pointed tip of a Type A point screw but the vestments of a Type B point screw. This combination makes them ideal for thin distance essence, resin plywood, compound accoutrements and several other assiduity- gauging operations.

Type BP These screws have a analogous thread style to Type B points but with a slightly longer and more pointedtip.However, a Type BP point is a thread forming screw suitable for use in heavy and featherlight distance essence, plastic and other accoutrements, If you ’re working on a design with deranged holes.

Thread Cutting Screw Points

Thread slice screws work like tone-tapping screws and can help you produce new holes in different accoutrements like wood and essence. Due to the way a thread cutting screw is designed, it does n’t take important necklace to apply them. Minimum stress is placed on the material, dwindling the chance for product damage.

Common types of thread cutting screws include

Type F Type F screw points are a type of thread slice and tone-tapping screw with cutting edges and a blunt and phased end at the tip. These features make it useful for heavy accoutrements, like cast iron, distance essence, brass and some plastics.

Type D/ Type 1 Type D screw points — also known as Type 1 points — are a thread slice point with a single flute. Type D tips are suitable for field relief and general use operations.

Type G Type G screw points are blunt and have singular places to produce sharp slice edges.

Type 17 You can use a coarse, sharp Type 17 screw tip for wood and field relief operations.

Type 23/ Type T Type 23 points, also known as Type T points, bear minimal tightening necklace and are good for chip clearing and maximum thread slice.

Type 25/ Type BT Type 25 points, called Type BT points, are analogous to Type 23 points, except they've coarser vestments for use with softer accoutrements, like plastic.

Thread Forming Screw Points

Thread forming screws have a high and low thread. These screws displace and shape the material while in stir, securing it. They generally have a blunt end for use with high- performance thermoplastics, distance essence, plastic and compound accoutrements.

Thread forming screw points include

Type C Type C screws have a blunt and phased point and bear a advanced driving necklace. You can use these with heavy distance essence, die castings and analogous accoutrements.

Type CA Type CA screw points have either fine or coarse vestments and a pointed, gimlet tip.

Type PT Type PT screw tips are the ideal result for low- viscosity accoutrements, similar as nylon or wood, that you want to avoid cracking or dicing during screw installation.

Type “ TT” “ TT” tips, or “tri-round” tips, roll accoutrements to form matching vestments without producing any chips. This means you can drive the screw in with lower necklace than you would with other thread

forming screws.