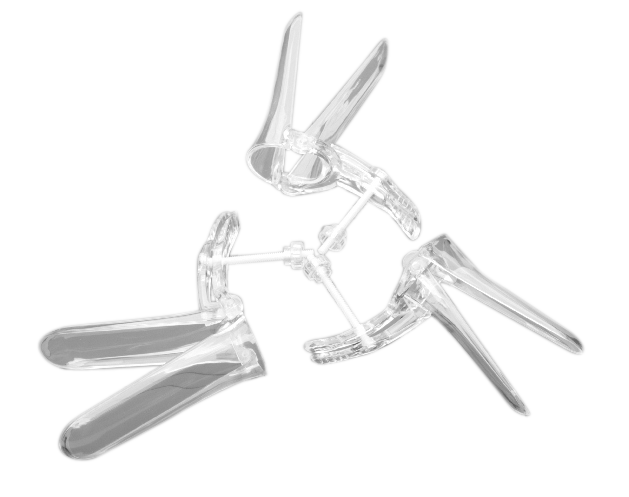

Screw Type A

When it comes to women’s health, the use of a vaginal speculum is essential. But what are the advantages of using a screw type vaginal speculum? Read on to discover the advantages of using a screw type vaginal speculum! and how it can be used for checking and treating gynecological diseases in hospitals or clinics.

| Ref. No.: | Size: | Packing: | Ctn size: |

|---|---|---|---|

| NMDE710101 | S | 1pc/poly bag, 100PCS/ CTN | 50x38x32cm |

| NMDE710102 | M | 1pc/poly bag, 100PCS/ CTN | 50x38x32cm |

| NMDE710103 | L | 1pc/poly bag, 100PCS/ CTN | 50x38x32cm |

A vaginal speculum is a medical device that is used to help visualize the vagina and cervix during a gynecologic exam. It is also used to help obtain samples of tissue or fluid from the vagina or cervix for testing. Vaginal speculums come in many different sizes and shapes, but all have a handle and two blades that open and close like a pair of scissors. The most common type of vaginal speculum is the metal, screw type. When inserting the vaginal speculum, the examiner will first lubricate thedevice and then insert it into the vagina. The blades of the speculum are opened once it has been inserted far enough into the vagina so that they can be placed on either side of the cervix. The examiner then opens the blades slightly so that they can get a good view of the inside of the vagina and cervix. Samples of tissue or fluid can be collected by swabbing them with a cotton-tipped applicator or by using a small brush. Biopsies can also be taken with a small punch biopsy instrument.

The screw type vaginal speculum has a number of special features that make it an ideal choice for many women. First, the screw type design means that the device can be inserted and removed without having to remove any clothing. This is a great advantage for women who are self-conscious about their bodies or who do not want to have to remove their clothes in public. Second, the screw type design also allows the user to adjust the angle of insertion, which can be helpful in providing a more comfortable experience. Finally, the screw type vaginal speculum is made from medical grade stainless steel, which makes it durable and easy to clean.

If you are looking for a vaginal speculum, you may be wondering why you should choose a screw type over another type. There are several reasons why screw type vaginal speculums are a good choice:

1. They are easy to use. Screw type vaginal speculums have a handle that you can twist to open and close the blades. This makes them much easier to use than other types of vaginal speculums, which can be difficult to open and close.

2. They are less likely to cause discomfort. Because screw type vaginal speculums have a smooth opening and closing motion, they are less likely to cause discomfort than other types of vaginal speculums.

3. They provide a better view. Screw type vaginal speculums tend to provide a better view than other types of vaginal speculums because the blades can be opened wider. This allows you to get a better look at the inside of the vagina.

4. They are easy to clean. Screw type vaginal speculums are easy to clean because they have fewer parts than other types of vaginal speculums. This means that there is less chance of bacteria build-up, which can lead to infection.

There are three main types of screw type vaginal speculum: the Wickham, Graves, and Deschamps. The Wickham speculum is the most commonly used type of screw type vaginal speculum. It is made up of two blades that are hinged at the top and bottom. The blades are opened and closed by turning a knob at the top of the handle. The Graves speculum is similar to the Wickham speculum, but it has only one blade. The blade is hinged at the top and bottom and is opened and closed by turning a knob at the top of the handle. The Deschamps speculum is made up of two blades that are hinged together in the middle. The blades are opened and closed by pushing or pulling on a rod that runs through the middle of the handle.