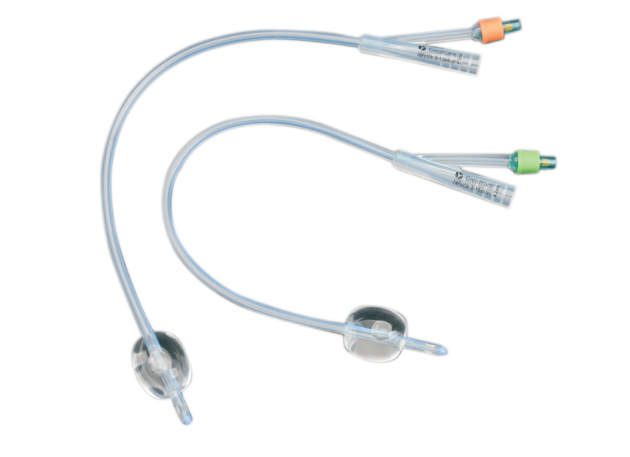

Two Way standard (plastic valve)

There are many types of valves on the market today, each with their own unique purpose. But when it comes to two way standard plastic valves, there are few that can match its versatility. In this article, we'll take a close look at what this valve is, how it works, and some of the many ways it can be used.

| Ref. No.: | Size: | Balloon capacity: | color: | Qty.Cs: |

|---|---|---|---|---|

| NMU201132 | 12 Fr/ch | 5ML | White | 400 |

| NMU201134 | 14 Fr/ch | 5ML | Green | 400 |

| NMU201166 | 16Fr/ch | 30ML | Orange | 400 |

| NMU201168 | 18 Fr/ Ch | 30ml | Red | 400 |

| NMU201170 | 20 Fr/ch | 30ml | yellow | 400 |

| NMU201172 | 22 Fr/ch | 30ml | Violet | 400 |

| NMU201174 | 24 Fr/ch | 30ml | Blue | 400 |

There are many types of valves on the market today, each with their own unique purpose. But when it comes to two way standard plastic valves, there are few that can match its versatility. In this article, we'll take a close look at what this valve is, how it works, and some of the many ways it can be used.

A two way standard plastic valve is a type of valve that is used to regulate the flow of fluid in a piping system. It is a simple device that consists of a body, a seat, and a plug. The body of the valve is connected to the piping system, and the seat is located inside the body. The plug is attached to the seat and has a hole in the center that allows fluid to pass through. The plug can be moved up or down to open or close the valve. When the valve is open, fluid can flow through the piping system. When the valve is closed, fluid cannot pass through the piping system.

A Two Way Standard plastic valve is a specialized type of valve that is designed to allow for two-way flow through a piping system. This type of valve is often used in situations where it is necessary to control the direction of flow in a piping system, such as in a pump system or in a pipeline. The Two Way Standard plastic valve is operated by a handle that is attached to the top of the valve body. The handle can be turned to one of two positions: the open position and the closed position. In the open position, the valve allows for two-way flow through the piping system. In the closed position, the valve blocks all flow through the piping system.

A two way standard plastic valve can be a great addition to your home. There are many advantages to having one, including the fact that they are:

1. Easy to install – You won’t need to hire a professional to install a two way standard plastic valve. In most cases, it’s a simple matter of following the instructions that come with the valve.

2. Inexpensive – Two way standard plastic valves are very affordable, making them a great option for budget-minded homeowners.

3. Durable – A well-made two way standard plastic valve will last for many years, providing you with years of trouble-free operation.

4. Low maintenance – Unlike some other types of valves, there is no need to regularly maintain a two way standard plastic valve. Simply install it and forget about it!

5. Versatile – Two way standard plastic valves can be used for a variety of applications, such as regulating the flow of water in your home’s plumbing system.

There are a few disadvantages to using a two way standard plastic valve. One is that they aren't as durable as other types of valves. They can also be difficult to install, and you may need to hire a professional to do it for you. Additionally, they don't always provide a tight seal, which can lead to leaks.

There are a variety of two way standard plastic valves on the market, each with its own advantages and disadvantages. It can be difficult to know which one is right for your needs. Here are a few things to consider when choosing a two way standard plastic valve:

-The type of material you need the valve to be made from.

-The size of the valve.

-The pressure rating of the valve.

-The temperature rating of the valve.

-The application the valve will be used for.

With so many factors to consider, it is important to consult with an expert before making a purchase. At Plastic Valve Manufacturer, we have over 25 years of experience helping customers choose the right valves for their needs. Contact us today and let us help you find the perfect two way standard plastic valve for your application.